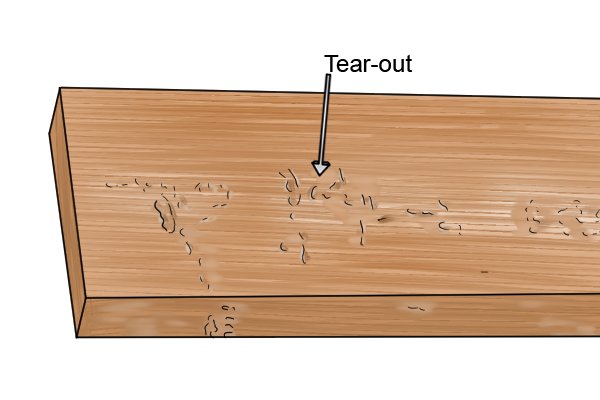

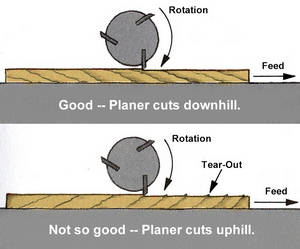

No matter what tool you're using, the best way to reduce tearout is to surround the blade or bit with a zeroclearance surface This is equally important on the band saw, drill press, miter saw, or table saw A zeroclearance insert creates the smallest amount of open area around the blade to support the wood fibers surrounding the cut as14 Ways To Avoid Wood Bowl Grain Tear Out 1 Start with a sharp bowl gouge A sharp bowl gouge might seem obvious, but it is the single most significant factor in reducing grain tear out Imagine the end grain fibers like little hairs If those hair get hit with a If the tear out isn't really deep, try wetting the surface you're about to plane with some water, let it sit for about a minute then run it back through your planer taking a very light cut The water will swell the softer fibers and they'll act as a cushion and help eliminate tear out

Planning Tear Out Problem By Gixxerjoe04 Lumberjocks Com Woodworking Community

Cost to tear out wood floor

Cost to tear out wood floor- Tear out occurs when the blade exits the top side of the wood and catches the veneer To prevent this from happening, apply masking tape to the top side of the wood that will be cut Then remove To eliminate the tearout on the 2x4, slip a 1x between it and the fence I take a piece of 1/2" MDF and use double stick tape to stick it to the back fence I also took a piece of 1/4" melamine and made a new insert The first time you cut through this, it becomes a zero clearance insert and you will get no tearout

Q A Veneered Plywood Tear Out Popular Woodworking Magazine

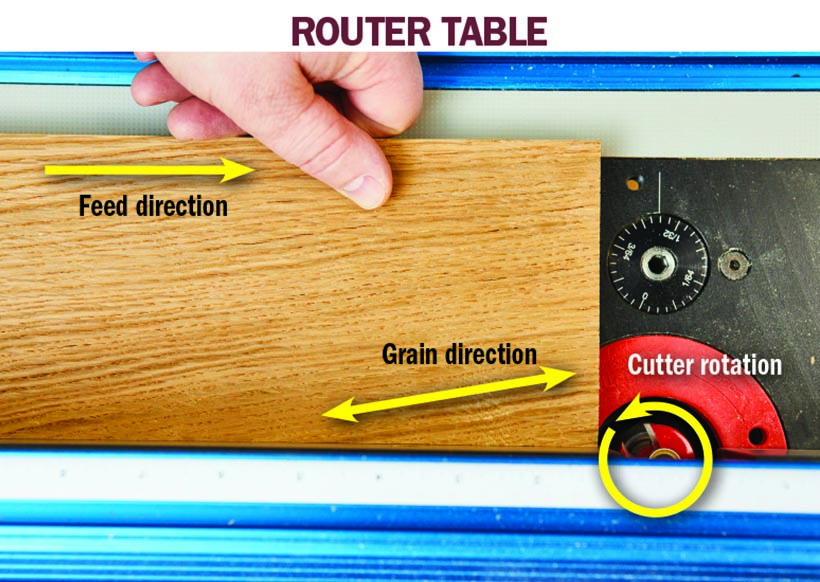

Here is a short introduction into bearing, shear, and tearout stresses in bolted joints and how complex they can beAvoid tearout when routing All about tearout Few things frustrate a woodworker like painstakingly shaping a curvy workpiece, only to have a router General rules Here are some general rules to help reduce the chances for tearout Use a sharp bit Dull bits chop at Use a sharp bit Dull bits Tablesaw tearout occurs as the saw teeth exit the work, breaking through and pushing aside the outermost layer of wood fibers rather than severing them cleanly Tearout is not really an issue when ripping;

ALL SIZES BULK (12pc to 100pc) Unfinished Wood Laser Cutout Solid Wide Teardrop Tear Drop Earring Jewelry Blanks Shape Crafts Made in Texas TexanWoodCrafts 5 out of 5 stars (2,760) $799 FREE shipping Add to FavoritesCracks, divots, holes, or rot can crop up on wooden surfaces due to ordinary wearandtear, accidents, and during doityourself projects Fortunately, wood fillers—which come in water Product Overview The QEP Reversible ErgoScraper adds comfort and increases force when scraping and prying Can be converted from 5 in to 3 in wide (or 5 in to 7 in) Ideal for scraping tight areas Better leverage and durability Great for removing tile, wood, laminate, stone, carpet, ice and roofing

With good quality wood the tearout is there but you need a magnifying glass to see it and sanding with 2 will take it away for more stubborn punky wood that won't respond to water a shelac with twice the alchohol will work well It will penetrate, dry in a few minutes, is compatible with most finishes, and the shelac locks the fibersTeardrop wood plugs carved wood plugs for stretched ears carve tear drop shaped gauge made from sono wood one pair 8mm 30mm P9 TwoFeatherConnection 5 out of 5 stars (4,770) $1099 Favorite Add to Dampening your wood, taking finer and slower cuts, sharper blades, attention to grain direction all these strategies will help and cumulatively they will usually prevent most tearout issues and minimize the ones that remain When you have done all that and still have some tearout that cannot be cut out or used on a nonvisible face

Secrets To Machining Solid Wood Woodworking Network

Avoid Tearout By Reading The Grain

Be sure to have a sharp saw blade If you use a rolling rubber hold down clamp you can feed the wood from left to right and therefore avoid tear out I have used this method succesfully in the past, but I never tried for 40 pieces only for a ocasional piece This method demands a lot from the operator, because the wood want to run away from you so you need some king of brake suystem What's the Difference Between Bearing, Shear, and TearOut Stress?

How To Know If You Have Wood Floors

Wood Magazine Here S How To Avoid Tearout When Milling Facebook

Drill without damage 1 Start with the right bit Doitall twist bits are inexpensive and designed to punch through wood, metal, and plastics 2 Back up your cut Regardless of bit choice, any time you punch metal through wood, unsupported wood fibers on the back 3 Drill from both directionsHow To Prevent Drilling Tear Out Any piece of wood scrap can be used as a backer board For a more permanent backer board, many woodworkers attach pieces of scrap wood to their drill press table with screws driven up through the guide holes in the table In addition to preventing tearout, a wood auxiliary table on your drill press helps Wood can also be torn out if a joint is suddenly put under greater pressure than the wood fibers can tolerate—such as when cabinet or drawer with screwed joints is dropped on a hard surface Here are five different solutions you can try when screws loosen or tear free of the wood they are supposed to be holding

Planning Tear Out Problem By Gixxerjoe04 Lumberjocks Com Woodworking Community

Possible Problems When Using A Plane And How To Solve Them Wd Tools

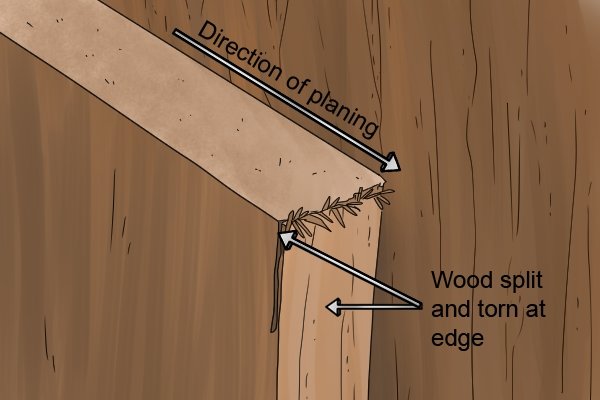

Generally, tearout happens when routing across the grain, turning corners or removing too much material in one pass Don't let tearout spoil a perfectly good piece of wood or your peace of mind A few good router tips are all you need Tip #1 Dial it back and slow downOne of the more difficult challenges new and intermediate wood turners face is how to deal with torn grain areas on their projects while turning Sometimes, even with the sharpest tools and the best techniques, you torn grain can develop In this article you will learn how to prevent torn grain if possible and how to effectively deal with it if all else failsWhen the cutting process is performed in the wrong direction the fibers being cut do not have supporting longer wood fibers underneath, so they break off and tear when the bowl gouge passes Wood Bowl Turning Rotation

Q Tbn And9gcqourodg5ya6car6zcd8o3ppl5owwiyukgsgwuou30 Usqp Cau

How Do I Mitigate This Tear Out Ideally With Hand Plane And Scraper Woodworking Stack Exchange

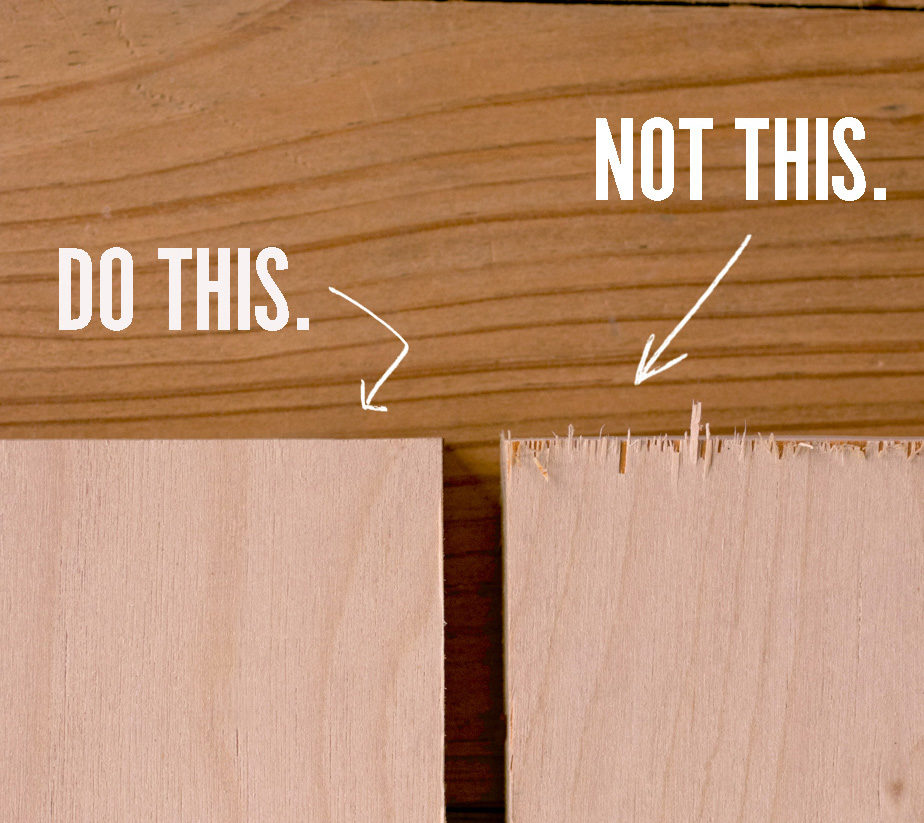

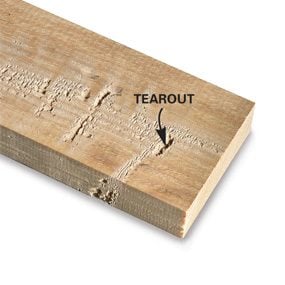

Tear out happens because the wood fibers on the edge of the board are ripped by the blade instead of being cut That ripping happens because the wood fiber tears under the force from the blade before it can be cut because the fibers on unsupported Step 6 Tear Down Decking Joists and Rim Joist Pry the decking joists away from the frame If the joists are large and hard to remove, pound them loose first using a large sledgehammer Step 7 Dig Out Supporting Deck Posts Dig up soil around the deck posts with a shovel in order to loosen them The wood's fibers are likely to catch and break apart ahead of the cut, producing tearout But when you run the router with the grain (see photo, right), you get a smooth cut Feeding your stock so the grain direction crashes head on into the bit rotation is like running your finger the wrong way on a feather

Avoid Tear Out When Routing Wood Magazine Woodworking Kits Woodworking For Kids Woodworking Storage

Watch This How To Stop Tearout Finewoodworking

Tear out happens when the grain wants to split, chip, or fracture, due to the wood itself, vibration from the tool, vibration from the balance of the wood, vibration from the lathe or its foundation, or vibration from how far the wood projects from one or two centers The more accurately aligned the centers are, the less vibration alsoMore Splintering and TearOut Tips The more porous the wood, the more likely it is to splinter Slower, shallower cuts will reduce the splintering Climb Cutting can make tearout less like than Conventional Milling Spray a sealer like laquer on the wood to give it a little more support Tips to minimize Router Burning WoodWood and pulled soon after driving However, if common smoothshank nails are driven into green wood that is allowed to season, or into seasoned wood that is subjected to cycles of wetting and drying before the nails are pulled, they lose a major part of their initial withdrawal resistance The withdrawal resistance for nails driven into wood that

Wood Block Tear Out In Brittle And Mixed Failure Modes Of Timber Rivet Download Scientific Diagram

Cutting Plywood Top Tips Bob Vila

So any splintering or tearout is going to happen on the bottom of your workpiece The best option to minimize splintering is to use what is called a zeroclearance insert Every table saw has a throat plate that sits around the saw blade and it's main purpose is to support wood, so small pieces of wood don't go into the hole around the bladeWood bowl grain tear out on wood bowls can be controlled Ways to address wood bowl grain tear out include tools, cut direction, lathe speedPreventing plywood tear out all comes down to three things Preparation Technique Execution With a little bit of knowledge and the proper tools, you don't ever need to witness those torn out plywood edges again Here are a few ideas to try and prevent plywood tear out Consider buying wood already to size;

3

Planes And Grains Wonkee Donkee Tools

How to Prevent Tear Out When Drilling a Hole Drill the hole partway through the front of the stock until the tip of the bit protrudes out the back of the board Flip the board over, and position the bit in the pilot hole Drill the rest of the way through Joe Truini is a seasoned contractor, accomplished author and hosts Simple Solutions on• Row TearOut Capacity • Group TearOut Capacity 11 NDS Dowelfastener Connections • 15 NDS Chapter 12 (New location) • Can be used for any dowelshaped fastener • Ild lt l d ithd l iiIncludes lateral and withdrawal provisions • Bolts • Lag screws • Wood screws • Nails Spikes 12 • • Drift bolts • Drift pins If you look closely at a bit of tear out you will see that the fibres are pulled away slightly away from the cut line and are bent back The light scoring makes a weak point where the fibre breaks instead of "tearing Out"

Stock Wood Tear Out How Are We Fixing These The Carbine Collector S Club Page 1

Tackling Tear Out At The Tablesaw 6 Simple Steps For Cleaner Cuts

Tear out happens because the wood fibers get caught on the drill bit and pushed out the wood, with a sacrificial board supporting the wood fibers at the exit point of the tool you can prevent tear out this is called zero clearanceTEAROUT & DISPOSAL The first step in any new floor installation is the removal and disposal of your old tile, wood, or carpet flooring Usually a timeconsuming process depending on the job, removal and disposal can be a hassle for any homeowner As an allinone solution, Ryno Custom Flooring Inc can provide fullservice removal and disposalLearn how to avoid end grain tearout when using your power tools WOOD magazine's Jim Heavey shows you how to eliminate unsightly splintering left behind f

Avoid Tearout With This Simple Trick The Wood Whisperer

Wood Tearout On Cnc Woodshop Dallas Makerspace Talk

One approach that involved a complete tearout of the existing wood windows is shown below The details for both the existing wood windows and the new wood windows are included The first step is to replace the existing wood frames with new treated wood blocking at the head and jambsWood Turning 7 Tips STOP end grain tear out wood bowl woodturningYear out can be a huge issue and create all kinds of frustration Not to worry,these 7 Tips, Sharp knives and slower feed can help with tear out There are figured species, like birds eye maple or curly cherry, to name two, where the grain goes around in a circular pattern or abruptly changes direction When you hear about York angle frogs on a smoothing plane, the blade angle has been raised to engage the wood at a steeper angle of

No More Tearout

Avoid Tear Out When Routing Wood Magazine

I'm using super sharp tools and have tried sanding sealer then scraper still have the tear out I've tried sanding sealer and then 80 grit, still tear out I've tried sanding sealer then 1 grit and STILL tear out So my question is "will I ever be able to get rid of it?" or is this the nature of the woodIt's cuts made across the grain that see damage Truth is, tearout from sawing is unavoidableIt helps to eliminate tearout, but also burning as well Wood that burns easily like maple will require an extra pass or two unless you really feel like sanding out a ton of burn marks From the original questioner I was going to make two passes, however because the legs on the knife trim up the moulding, I would have to adjust my guide

2 033 Tear Out Photos Free Royalty Free Stock Photos From Dreamstime

How To Cut Plywood With A Jigsaw Without Splintering Saw Features

What Causes Tearout and Splintering on Wood Splintering and tearout are often used synonymously – and they're more likely to occur when you're making a crosscut in the plywood This is because the wood fibers in the veneer are oriented so that they run the length of the board, so you have to cut through all of themGroup tearout (Fig 4) describes the tearout of a "plug" of wood bounded by the fastener group InAppendixE,theallowabletearoutcapacityofagroup of "n" rows of fasteners is estimated as Z ZZ GT FA RT RT n tgroupnet ′ = ′ ′ −−′ − 1 22 E41 where ZGT′ = allowable group tearout capacity ZRT1′ = allowable row By tearout I don't mean the usual and I'm not sure if it is even the right term Basically, the wood that is just short of end grain will not sand smooth It might not be noticed by most but it irritates the hell out of me Even when I try to sand it by hand I can't remove the imperfection With a relatively soft wood like Cherry it is not

Epoxy Makes Tearout Disappear Finewoodworking

How To Cut Plywood Without Tear Out Wood Projects Plans

Climb cutting accomplishes several things that will reduce tear out and splintering One, it reduces cutting forces, so there is less forcing trying to tear out the wood Two, chips are cut out as little Cshaped pieces They are thin at one end and thick at the other How to Master Hardwood Floor Removal in 5 Steps Step 1 Gather the Right Tools for the Job Step 2 Prepare to Tear Out Your Wood Floors Before you get started, you'll need to spend some time getting the space Step 3 Protect Your Subfloor and Prepare Your Hardwood Hardwood floors are attached

Q A Veneered Plywood Tear Out Popular Woodworking Magazine

Grain Tear Out In Ash Telecaster Guitar Forum

Simple Ways To Prevent Tearout On A Table Saw 8 Steps

Q A Veneered Plywood Tear Out Popular Woodworking Magazine

The Bevel Down Planes Will Readily Repair Bevel Up Tear Out Paul Sellers Blog

Your Guide To Tear Out Popular Woodworking Magazine

Thwart Router Bit Tear Out

Hand Planing Pine Nasty Tear Out Everywhere Woodworking

How To Prevent Insane Tear Out Woodworking

The Card Scraper Cleans Up Glue Tear Out Nicks Or Bumps Woodworking Blog

Six Board Chest Tear Out Bleck She Works Wood Leather

Kapex Tear Out Issues Frustrated And Disapppointed With Festool

How To Cut Plywood Without Tear Out Handyman Tips

4 Ways To Avoid Tearout At The Table Saw Youtube

How To Prevent Tearout And Splintering When Cutting Plywood Once And For All Manmadediy

3

How To Avoid Topside Tear Out Chipping When Drilling Wood Discussion Discourse South London Makerspace

Preventing Tear Out When Crosscutting Plywood Youtube

Tearout My Battle With Mahogany T R I A L E R R O R

Avoiding Tearout When Cutting Veneered Sheets

Tear Out When Plate Making W A Router Woodworking Stack Exchange

End Grain Chamfer Tear Out Nc Woodworker

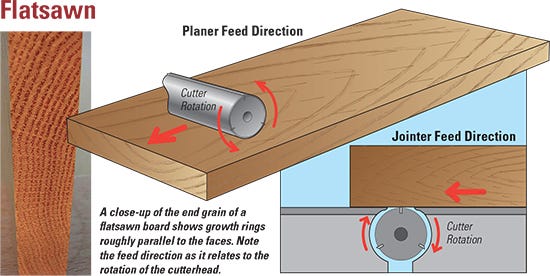

Secrets To Reading Grain Pressreader

Reading Wood Grain Don T Fight The Fibers Finewoodworking

How Do I Avoid Tearout When Milling Wood Wood Magazine

Wood Block Tear Out Resistance And Failure Modes Of Timber Rivet Connections A Stiffness Based Approach Journal Of Structural Engineering Vol 140 No 2

Floor Tear Out Disposal Ryno Custom Flooring Inc

Amazon Com Wood Groom Brush Deshedding Grooming Tool Professional Pet Wooden Groomer Ergonomic Design No Hurt For Dogs Cats And Horses 5 Inch

Tackling Tear Out At The Tablesaw 6 Simple Steps For Cleaner Cuts

Stop Tearout In Plywood The Wood Whisperer

Secrets To Machining Solid Wood Woodworking Network

How To Use A Benchtop Wood Planer Diy Family Handyman

Simple Ways To Prevent Tearout On A Table Saw 8 Steps

How To Fix Common Mistakes Made When Building Things Out Of Wood Core77

Mahogany Tear Out Fix Ca Or Automotive Filler Pics Telecaster Guitar Forum

Prevent Router Tearout Blowout Chips Woodworking

Repairing Tear Out General Woodworking The Patriot Woodworker

Drilling Perfect Holes 9 Steps Instructables

Avoid Tearout By Reading The Grain

Don T Tear Up Over Tear Out The Renaissance Woodworker

14 Ways To Avoid Grain Tear Out With Wood Bowl Turn A Wood Bowl

Bad Tear Out On Helical Head Need Advice By Fiddy Lumberjocks Com Woodworking Community

Is Green Wood Prone To Tear Out Woodworking Talk

Troubleshooting Maple Moulder Tear Out

Don T Tear Up Over Tear Out The Renaissance Woodworker

Stop Tearout In Plywood The Wood Whisperer

Don T Tear Up Over Tear Out The Renaissance Woodworker

9 Diy Tips For Wood Floor Scratch Repair Bob Vila

Pin On Tools And Techniques

9 Tips For Beating Router Tear Out Popular Woodworking Magazine

14 Ways To Avoid Grain Tear Out With Wood Bowl Turn A Wood Bowl

Selkie Wood Works Priscilla S Bowl End Grain Tear Out And What To Do About It

1

How To Remove Wood Flooring Dumpsters Com

Tear Out In The Wood Ideas By Mr Right

Repairing Or Filling A Tear Out Woodworking Talk

Tackling Tear Out At The Tablesaw 6 Simple Steps For Cleaner Cuts

How Woodworkers Tame Tearout Finewoodworking

Help With Dealing With Tear Out

Tear Out On Hickory Panels General Woodworking Talk Wood Talk Online

John S Anti Tear Out Weapon Of Choice In Wood Working Hnt Gordon Co Classic Planemakers Australia

Nicks In Planed Walnut And Birch Wood By Woodworker33 Lumberjocks Com Woodworking Community

Fixes For Plywood Tear Out I Don T Need It To Look Immaculate Just Flush And Acceptable Woodworking

Zebra Wood Shelves Tearing Woodworking Talk

Simple Ways To Prevent Tearout On A Table Saw 8 Steps

Wood Block Tear Out Resistance And Failure Modes Of Timber Rivet Connections A Stiffness Based Approach Journal Of Structural Engineering Vol 140 No 2

How To Avoid Topside Tear Out Chipping When Drilling Wood Discussion Discourse South London Makerspace

14 Ways To Avoid Grain Tear Out With Wood Bowl Turn A Wood Bowl

New Dewalt 735 Planer Causing Tear Out On Walnut Any Ideas Why I Ve Heard Of Tear Out With Endgrain But The Board End On Top Used To Be Squared Off Ran Probably

3 Planing Know How

Your Guide To Tear Out Popular Woodworking Magazine

Table Saw Inserts Tear Out Test On Natural Woods Fail Youtube

Avoid Tearout With This Simple Trick Youtube

Help With Dealing With Tear Out

Flooring Before And After Reveal Wood Looking Tile 365 Days Of Slow Cooking And Pressure Cooking

Template Routing End Grain Tearout General Woodworking Talk Wood Talk Online

How To Prevent Tearout When Using A Saw Toolboxtoday Com

Skews Part 2

Your Guide To Tear Out Popular Woodworking Magazine

Wood Failure Parallel To Grain A Block Tear Out Bounded By The Rivet Download Scientific Diagram

0 件のコメント:

コメントを投稿